SEZ operations

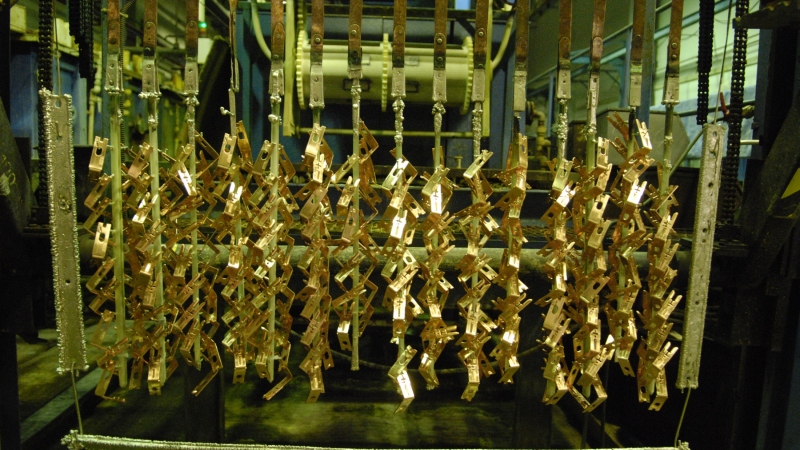

Surface Treatment

We offer various galvanic surface treatments, including mass and barrel galvanizing, as well as blue chromating in automatic line no. 1. In automatic line no. 2, we provide mass and barrel tinning, nickel plating, and silver plating. In 2008, we completed the automation of the galvanic surface treatment process, ensuring high-quality outputs.

The maximum dimensions of parts we can accommodate are 1200 x 800 x 300 mm.

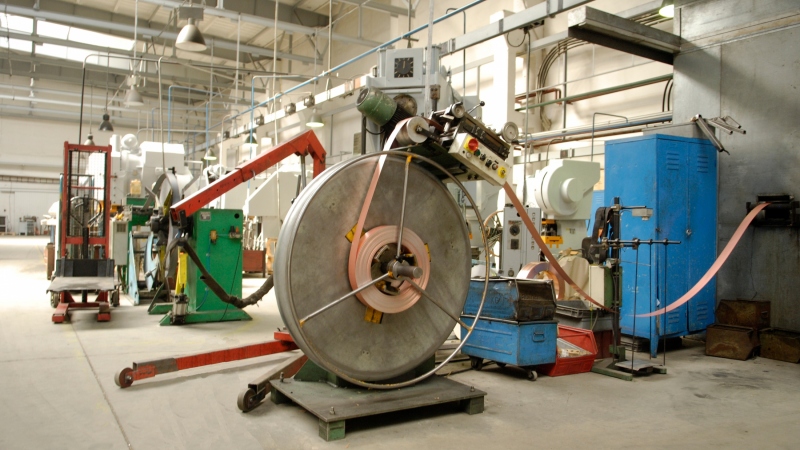

Press shop

The primary production is focused on mass-produced formed parts and metal-cut components. The galvanizing process and the paint applied to the part surface are the two surface treatment methods used. The primary production also deals with the welding of metal sheet vessels and other structures. In cooperation with the supporting units of the joint-stock company, the plant is able to fully cover parts manufacturing in accordance with delivered drawings. Another possible cooperation lies in the manufacturing of parts based on finished preparation delivery. The parts are manufactured using simple, sequenced, and combined tools for processing metal sheets and strips with thicknesses ranging from 0.1 to 8 mm, made of Fe, Cu, Ms, and AI.

The Press Shop is equipped with the latest automatic high-speed BRUDERER BSTA 41 and BSTA 50 presses, with forming and assembling automatic BIHLER GRM 50s, forming automatic TALO 25 and TPO 25 A, and with traditional eccentric presses for mass production of components up to 2.5 mm thick and for small-scale production of 2 - 8 mm thick (occasionally up to 15 mm thick) metal components with forming forces ranging from 10 t to 160 t (LEN 10C, LEN 25C, A, LEN 63C, LEK 160, LEN 160F). The primary production also includes the resistance welding of subassembly and assembly units. Pneumatic spot-welding machines with power outputs of 4OkVA and 8OkVA, as well as pneumatic micro spot-welding machines with power outputs of 4kVA and 10kVA, are applied. The equipment is designed to weld Fe, Cu, Ms, Br, bimetal, and their combinations.

NEWS

- LEN 160 F press, including a leveller and a feeder - press force 160 t, number of strokes 55/min – for components with a maximum thickness of 4 mm and for 200 mm wide strips (products: Gewindering, components produced for EMBRACO, components produced for circuit-breakers).

- Burkhart EBU H63 press, including a leveller and a rotary feeder - press force 63 t, number of strokes 45-140/min – for components with a maximum thickness of 2 mm and for 200 mm wide strips (products: components produced for EMBRACO, components for circuit-breakers, cam switches, and EIM).

Machining shop

The parts are manufactured in the Machining Shop depending on the volume and complexity of the parts. The parts are produced using conventional technology, such as center, turret, and finishing lathes, milling, drilling, grinding machines, and threading machines. Mass production is carried out using automatic single-spindle turret lathes (A20, A2OB, A4OC), automatic long-turning lathes (AWA 4M, AWA 7, ADA 6, AWA 10, AWA 16, AWA 25), and automatic multi-spindle high-performance lathes (TORNOS SAS 16 DC).

Tubular rivet production is carried out at JUS. Continuous grinding is performed using 3M 182 and BB 10 centerless grinding machines. Precisely formed components are mass-produced using chuck and turret NC lathes (SPRY 40 NC). In addition to machining, this technology is also used for threads and thread wheel production using the plunge and partially continuous method (UPW 12,5.1, UPW 31.5.100).

NEWS:

ESOMATIC D2 Speed automatic machine – Designed to produce rotating components made of maximum D3 wire – including a rotary leveller and rotating shears.

Product assembly

- Assembly of HV devices and lifting equipment;

- Assembly of electrical devices: switches, sockets, and circuit breakers, as well as their accessories;

- The assembly is typically done manually using various tools and equipment or semi-automatically.

- The assembly is mainly performed by women due to the small size of the components.

- The assembly process also includes the production of sub-assembly units, testing, labeling, and packaging.